Basic Info.

Model NO.

HM08

IP Rating

IP66

Certification

CCC, CE, FCC, RoHS

Input Voltage

220V or as Per Local Condition

LED Chips Brand

Semileds

Wind Resistant Speed

Over 250km/Hour

Surface Treatment

Hot DIP Galvanization

Product Name

High Mast

Thickness of Galvanizing

85um

Service Door

Weatjer AMD Vamda; Resostamt Woth Heavy-Duty Lock

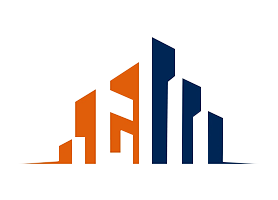

Winch

Double Drum Max.Load 1200kg

Stainless Steel Wire Rope

Grade/Ss 204 or SS304

Extension Leads

Multi-Core Cable

Luminaire

400W-700W LED Flood Light

Pulleys

Large Diameter

Lantern Fixing Arms and Plates

Welded to The Carriage

Transport Package

Wrapped with Felt Fabric or Woven Bag

Specification

2, 3, 4 section to be confirmed

Trademark

OEM/ODM

Origin

China

HS Code

73089000

Production Capacity

500set/Month

Product Description

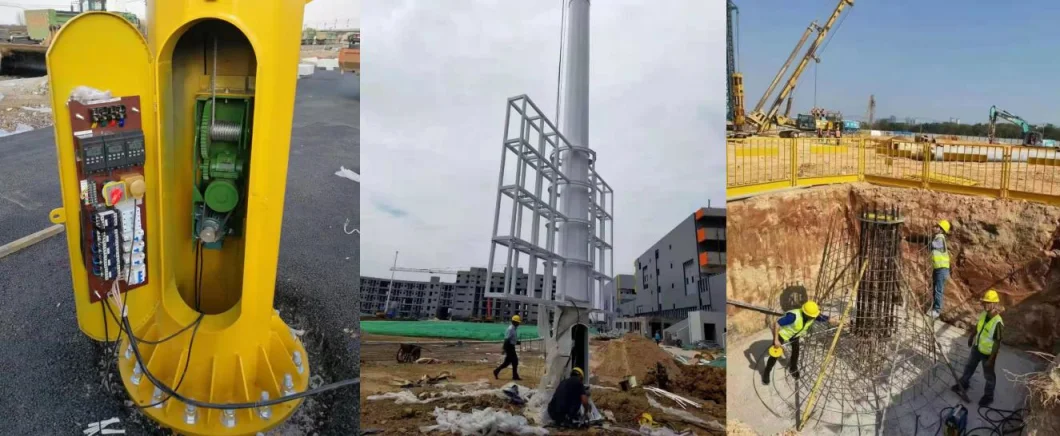

13m-50m hot dip galvanized High Mast Lighting

The business Philosophy of our company :Popular Price,Quality Stable,Fast Delivery, Best Service

High mast lighting is a type of site light fixture that is commonly used to illuminate large areas from a very high mounting height for storage, transportation, and pedestrian use and safety.

A high mast pole is a continuously taper polygonal cross-section that has one or more segment, used mainly to light over a large area. High mast lighting poles are used where today's most busy highways merge or intersect with each other. Generally, these types of lighting poles are manufactured from steel, and the surface units are hot dip galvanized .

The function of a high mast light pole is well qualified to account for the lighting load, tower weight, variable wind speeds, local soil conditions and a host of other relevant variables which needs to be considered while designing. Most of the mounted sections have even numbers of lights in the ring, with uneven numbers of lights used in rare instances.

Latch barrel with inner mounting bracket locker is mounted to an underside of the mast-top pulley assembly. All the steel cables are not exposed and more effectively protected.

Latching mechanism latched on steering arms can release strain on steel cables when in the operation position. The process of fastening on and off is stable and without vibration.

The bumper is designed on the luminary mounting bracket for avoiding direct damage between mast-top assembly and the raising luminary mounting bracket.

The leveling device for luminary support bracket is easy to operate and convenient to adjust level.

The Stadium High Mast are usually mounted with floodlights, and seen in places like stadiums, race course, etc. where high concentration of light is required over a small area.

The height of the pole and the number of units of floodlight are dependent either on the necessity for the requirement of the area, or as per the specifications mentioned by the client concerned.

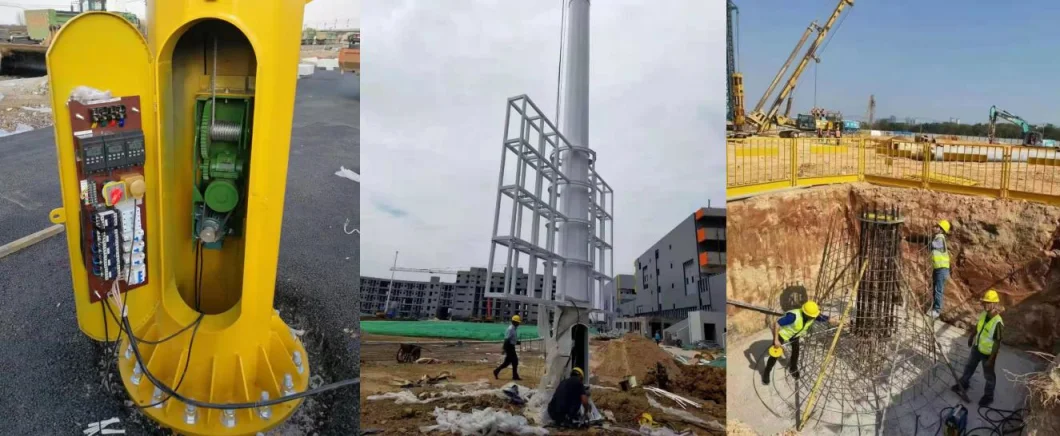

The high mast shaft, the base plate and the anchor bolts that are used to manufacture the stadium masts are went through analysis via software so as to design the same. The designing is done as per good standard, 'Standard Specifications for Structural Supports for Stadium Lighting and Luminaries'.

The Stadium High Masts are constructed and designed with continuously tapered steel with polygonal shape of sixteen sides.

Sheets of steel are folded accordingly to the required shape. And then with the help of an Automatic Arch Welding Machine, the sheets are welded longitudinally.

Depending on the height of the mast, shafts are constructed out of multiple segments.

The shafts are then equipped with a fixed head frame at the top to hold the flood lights.

Our company is one of the trusted names to offer solutions in manufacturing high mast lighting poles throughout the country ISO 9001-2015. We offer the best quality stainless steel lighting poles for transportation and lighting applications. We never compromised on our quality. We have acquired a wealth of experience in the structural, mechanical and electrical aspects of high mast lighting pole designing, production, and maintenance. That's the reason we are considered amongst one of the most trusted high mast pole manufacturers in the country.

Excellence in product quality is what we call our benchmark, eventually being the reason behind a strong repute amidst a loyal patron base all over the country.

If you have the demand for your customer's project, please send us your inquiry. we would do the best with our best popular price for you, to asist you win the pending project.

Deatails of High Mast:

No. of sections: 8-sided, 12-sided, 16-sided, 18-sided, 20 sided

Lantern Carriage& Material of construction: Subject to lamp quanity accordingly

A high mast pole is a continuously taper polygonal cross-section that has one or more segment, used mainly to light over a large area. High mast lighting poles are used where today's most busy highways merge or intersect with each other. Generally, these types of lighting poles are manufactured from steel, and the surface units are hot dip galvanized .

The function of a high mast light pole is well qualified to account for the lighting load, tower weight, variable wind speeds, local soil conditions and a host of other relevant variables which needs to be considered while designing. Most of the mounted sections have even numbers of lights in the ring, with uneven numbers of lights used in rare instances.

Latch barrel with inner mounting bracket locker is mounted to an underside of the mast-top pulley assembly. All the steel cables are not exposed and more effectively protected.

Latching mechanism latched on steering arms can release strain on steel cables when in the operation position. The process of fastening on and off is stable and without vibration.

The bumper is designed on the luminary mounting bracket for avoiding direct damage between mast-top assembly and the raising luminary mounting bracket.

The leveling device for luminary support bracket is easy to operate and convenient to adjust level.

The Stadium High Mast are usually mounted with floodlights, and seen in places like stadiums, race course, etc. where high concentration of light is required over a small area.

The height of the pole and the number of units of floodlight are dependent either on the necessity for the requirement of the area, or as per the specifications mentioned by the client concerned.

The high mast shaft, the base plate and the anchor bolts that are used to manufacture the stadium masts are went through analysis via software so as to design the same. The designing is done as per good standard, 'Standard Specifications for Structural Supports for Stadium Lighting and Luminaries'.

The Stadium High Masts are constructed and designed with continuously tapered steel with polygonal shape of sixteen sides.

Sheets of steel are folded accordingly to the required shape. And then with the help of an Automatic Arch Welding Machine, the sheets are welded longitudinally.

Depending on the height of the mast, shafts are constructed out of multiple segments.

The shafts are then equipped with a fixed head frame at the top to hold the flood lights.

Our company is one of the trusted names to offer solutions in manufacturing high mast lighting poles throughout the country ISO 9001-2015. We offer the best quality stainless steel lighting poles for transportation and lighting applications. We never compromised on our quality. We have acquired a wealth of experience in the structural, mechanical and electrical aspects of high mast lighting pole designing, production, and maintenance. That's the reason we are considered amongst one of the most trusted high mast pole manufacturers in the country.

Excellence in product quality is what we call our benchmark, eventually being the reason behind a strong repute amidst a loyal patron base all over the country.

If you have the demand for your customer's project, please send us your inquiry. we would do the best with our best popular price for you, to asist you win the pending project.

Deatails of High Mast:

No. of sections: 8-sided, 12-sided, 16-sided, 18-sided, 20 sided

Lantern Carriage& Material of construction: Subject to lamp quanity accordingly

Features of Lighting Pole:

| Height | 13-50m |

| Applications |

|

| Shape |

|

| Material |

|

| Surface Treatment |

|

| Wall Thickness |

|

| Joint of Poles |

|

| Welding |

|

| Joint of Poles |

|

| Base plate |

|

| Life Span |

|

Lighting Pole Style:

The pole would be exactly according to customer's request. Customized or drawing is welcome to be proceed.

POLE SHAPE (Customized Service)

POLE DESIGN(Customized Service)--CAD Design

3D Design

Wind-Resistant Design

POLE FORMING

POLE FORMING -Loss of Roundness of Tapered Pole <6%

-Maximum Processing Thickness 16mm

-Monthly production of 24 000

-1200T*4

WELDING

50 worker in the welding team to ensure each order of mass production finished without delay

All of the welder have CSWIP, experienced welder ensure our welding quality.

HOT-DIP GALVANIZING

Antiseptic treatment.

Galvanized layer no less than 86 microns.

Galvanized life no less than 20 years.

Rust Protection

POWDER COATING

Using high-quality pure polyester plastic powder.

The service life should not less than 20 years, meanwhile thickness≥80um

Meet the ASTMD339-83 standard.

Working Procedure of Mass Production of lighting post

Packing and Stock:

Our Team: